Heizwertmessung und Energiebasierte Lambdaregelung

Das Präzisions-Kalorimeter CWD2005 PLUS

Der Energiegehalt des Brenngases ist ein wesentlicher Prozessparameter für den stabilen Betrieb von Feuerungsanlagen. Änderungen der Bezugsquelle oder auch die zunehmende Beimischung von Fremdgasen (z.B. H2, Biogas, Flüssiggas (LPG, LNG)) führen zu deutlichen Schwankungen des Brennwertes.

Da diese Änderungen meist ohne Kenntnis des Endkunden und über undefinierte Zeiträume erfolgen, werden Instabilitäten im Prozess nur selten auf mögliche Zusammenhänge zurückgeführt.

Durch eine kontinuierliche Bestimmung des Energiegehaltes und eine entsprechende Kompensation mit Hilfe eines angepassten Regelkonzeptes ist es möglich, diesen Schwankungen kontrolliert entgegenzuwirken.

Als exklusiver Partner von Union Instruments für die Kundschaft aus der Glasindustrie empfehlen wir das Kalorimeter CWD 2005 PLUS.

Geliefertes Gas mit schwankender Zusammensetzung durch häufige Wechsel der Bezugsquellen

Zumischung von z.B. H2, Biogas, Flüssiggas (LPG, LNG) verändert die Gaseigenschaften

Dies hat Einfluss auf

- den Energiegehalt des Gases

- die Strahlungseigenschaften der Flamme

- den Luft- und Sauerstoffbedarf

Fazit: Für einen stabilen Prozess ist ein konstanter Energieeintrag ausschlaggebend. Die Gasmenge allein ist nicht länger hinreichend - sondern der schwankende Heizwert muss in die Berechnung mit einfließen. Das CWD Kalorimeter ist hierfür bestens geeignet.

Zuverlässige Onlinemessung (thermisches Messprinzip)

Kontrolle des Energieeintrages

STG Energiebasierte Lambdaregelung kompensiert Änderungen der Gaszusammensetzung durch Anpassung von Gas- und Brennluft/O2 Sollwerten

Regelung auch bei kurzfristigen Schwankungen möglich

kontinuierliche Messung von Heizwert, Wobbe, Dichte

Messgenauigkeit:

- Erdgas 30 - 48 MJ/m3 +/- 1,0 % Messwert

- Dichte rel.: +/- 1,5 % E

montiert in Indoor Schrank

- Schutzklasse IP65

- Maße (BxHxT) [mm]: 1000 x 1850 x 600

- Abgasanschluss: 100 mm Durchmesser

- Max. Abgastemperatur: 70 °C

- inkl. System zur Gasaufbereitung für trockenes Erdgas

- inkl. Kalibriergas-System

- Magnetventilblock 2-fach

- Brenner Typ H

- 2x Temperaturmessung (1x CWD Gerät / 1x Umgebungstemperatur)

- Incl. 3 x analoge Ausgänge (Heizwert, Wobbe Index, Dichte), 3 Relais (com, no, nc), LED-Dauerlicht; vorbereitet für Ethernet-Kopplung

Precise determination of Calorific Value, Density and Wobbe

All components in the fuel gas (including H2) are considered.

Proven and robust design

Self-monitoring of device and ambient temperatures

Minimal maintenance: only one calibration gas required with low consumption

Provides all necessary raw data for STG's patented "Energy Based Lambda Control"

Technische Beratung

Lieferung und Installation eines kompletten Messsystems mit Kalorimeter CWD2005 PLUS

Die Signalauswertung / Verbrennungsrechnung als integrierte Lösung im Prozessleitsystem liefert:

- Heizwert Hi (früher: Unterer Heizwert Hu)

- Brennwert Hs (früher: Oberer Heizwert Ho)

- Wobbe Index

- Stöchiometrische Luft-und Abgasmenge

- Dimensionslose Brennstoffkennzahlen nach Boie

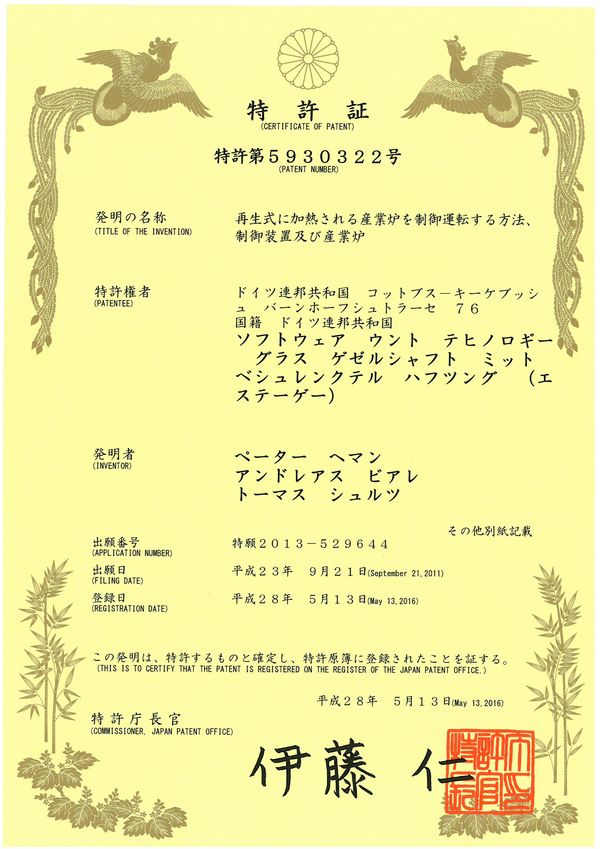

Optional: Patentiertes Regelungskonzept „Energiebasierte Lambdaregelung“, siehe unten

Energiebasierte Lambdaregelung

Die in den letzten Jahren stetig zunehmenden Probleme mit unvorhersehbaren Schwankungen der Gasqualität stellen insbesondere die Betreiber von Glasschmelzanlagen vor völlig neue Herausforderungen.

Um den daraus resultierenden Instabilitäten im Schmelzprozess kontrolliert entgegenzuwirken, hat die STG die „Energiebasierte Lambdaregelung“ entwickelt und seit mehreren Jahren erfolgreich im Einsatz.

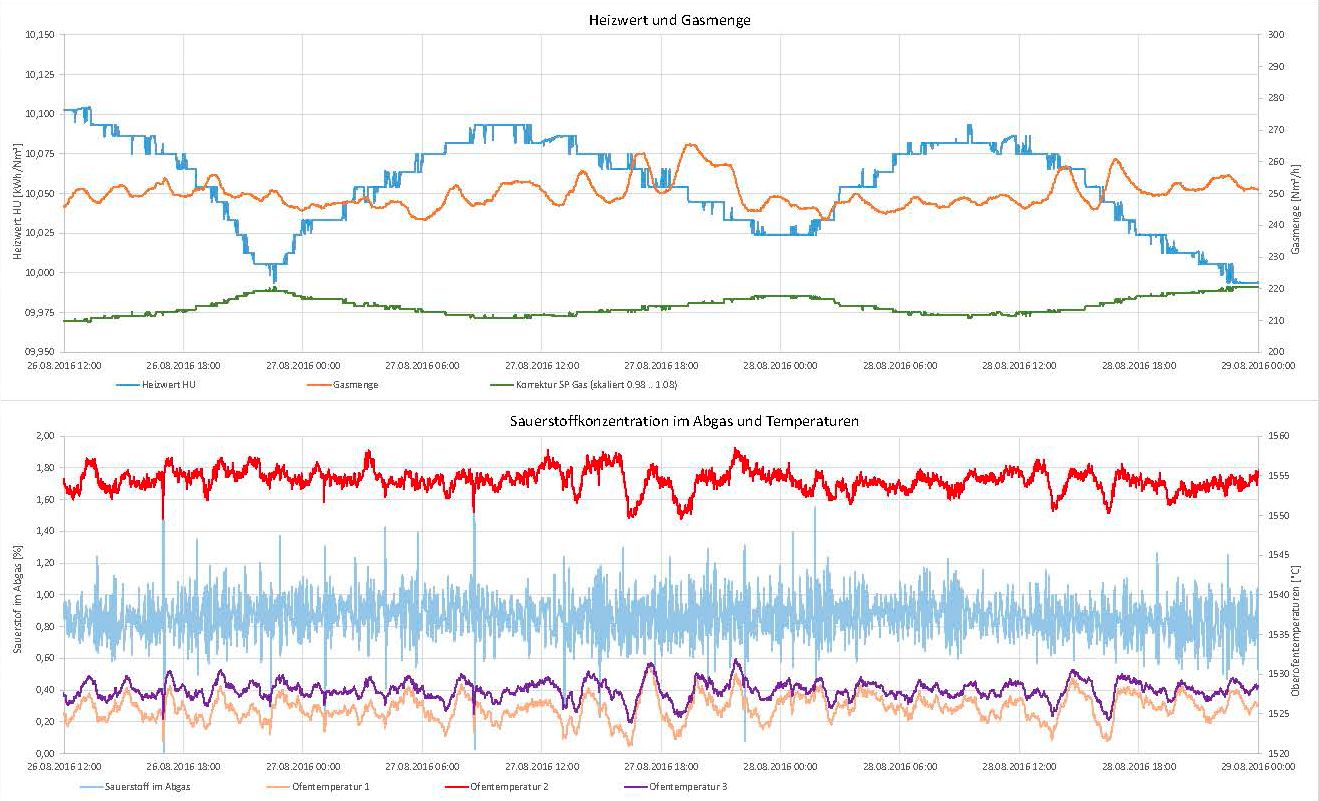

Die Heizwertmessung erkennt Änderungen in der Gaszusammensetzung.

Die STG-Sauerstoffsonden reagieren auf kurzfristige Änderungen im Prozess und sind ein zuverlässiger Indikator zur Bestimmung von Falschlufteintritt.

STG hat die Vorteile beider Systeme kombiniert und eine automatische Regelung für einen jederzeit stabilen Energieeintrag in den Schmelzprozess entwickelt.

Das (patentierte) Ergebnis spricht für sich:

Kompensation von Schwankungen der Gasqualität und des unkontrollierten Lufteintritts

Konstanter Energieeintrag (MW) in den Schmelzprozess

Prozessstabilität und konstante Glasqualität

Energieeinsparung (Brennstoff und Luft)

Reduzierung von Energieverlusten

Reduzierung der NOx-Emissionen

Begrenzung der CO-Emissionen

Verfügbar für Leitsysteme von Siemens und Rockwell (Allen-Bradley)

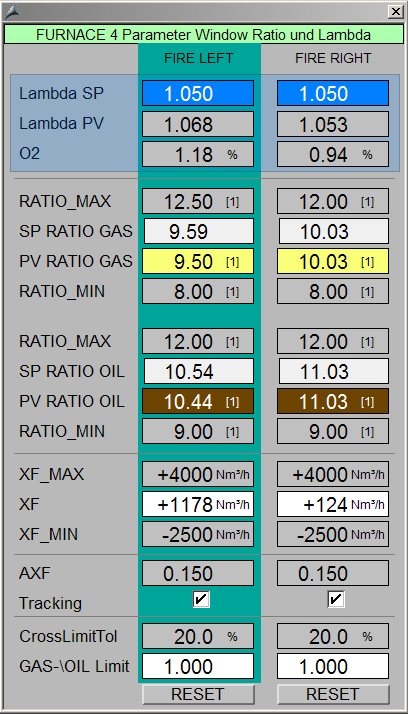

Patentierte automatische "Energiebasierte Lambdaregelung" für einen konstanten Energieeintrag in den Schmelzprozess:

- Kompensation von Schwankungen der Gasqualität

- Kompensation der unkontrollierten Luftmengen

- Aufrechterhaltung des optimalen Herdraumdrucks um Falschlufteintritt in die Schmelzwanne zu verhindern

- Kalorimeter / Chromatograph überwacht die Gasbeschaffenheit und stellt dem Leitsystem die benötigten Daten für Sollwert Gas [MW] zur Verfügung

- Sauerstoffsonden geben ein schnelles Feedback zu Änderungen der Verbrennungsparameter und fungieren für die Regelung als Indikator der Störgröße Falschluft XF, zur Korrektur der benötigten Brennluftmenge

Vollständige Integration in die Visualisierung (S7/WinCC; PCS7; iFIX; FactoryTalk)

Bereitstellung der Signale durch Modifizierung / Erweiterung der bestehenden Programme von Wannen-SPS und Visualisierung (z.B. zusätzliche Faceplates)

STG benötigt vorübergehenden Zugriff auf die Engineering Station mit gültiger Lizenz und dem aktuellen Programmstand

Installation und Inbetriebnahme durch STG-Programmierer/ Optimierung / Support über Fernzugriff

Verfügbar für Siemens und Rockwell / Allen-Bradley basierte Leitsysteme

- entweder als Erweiterung eines bestehenden Systems

- oder als integraler Bestandteil einer neuen Anlagensteuerung von STG

Ihr Ansprechpartner (CWD Kalorimeter)

Werner Bengsch